The energy efficiency, a marginal issue in the past, has become one of the dominant aspects in the development of the household appliances. A story that has lasted for twenty years and is far from seeing the end.

In recent years, the attention of industry and retailers to the energy efficiency has become increasingly strong. From design to production to packaging, there are several innovative solutions that companies have created to supply truly sustainable products. The history of energy efficiency has made great strides, achieving remarkable results: in this article we retrace the main steps and we show the possible future developments. In 1953 FIAT presents his washing machine at Milan’s Fair. But what does the fairs exhibit? Gas cookers, refrigerators, washing machines, vacuum cleaners, televisions and the first small appliances such as mixers and coffee machines. Practicality and functionality are what is required to the appliances: the optimism that dominates those years does not suggest a decrease of the resources, the oil crisis is far away and the climate has not yet begun to be a problem. It’s only during the first energy crisis that people begin to think that the fossil sources can not be infinitely available. Besides, in the same decade – the Seventies – the first suspicions of damages to the environment by the refrigerators with CFC begin. These are the first signs that times are changing and some manufacturers start to change their approach to the design of household appliances.

The energy comes to the fore

In 1998 the first energy labels for the household appliances appear in Italy, and the energy consumption becomes the feature that the consumer sees first: consumers’ behaviour starts to change, as well as the attention of producers. The result? In just 15 years, the landscape of the household appliances sales indicates an almost disappeared “E”class and shows purchases that focus on more efficient energy classes. Already in 2000, in Italy, the sales of refrigerators in A class or more (A+) accounted for 15% of all sold refrigerators, reaching almost 87% in 2008. The average energy consumption of the appliances strongly falls. Considering 100 the consumptions of 2003, we arrive at 81% in 2009 for the freezers, 86% for the refrigerators, 90 and 91% for the washing machines and dishwashers. In 2011, the European Union introduces a new energy labelling, because the old one is calibrated on obsolete energy classes thanks to the reached level of technology and energy efficiency. The new label includes three new classes (A+, A++ and A+++): the last one is the most virtuous and recently introduced.

In 1998 the first energy labels for the household appliances appear in Italy, and the energy consumption becomes the feature that the consumer sees first: consumers’ behaviour starts to change, as well as the attention of producers. The result? In just 15 years, the landscape of the household appliances sales indicates an almost disappeared “E”class and shows purchases that focus on more efficient energy classes. Already in 2000, in Italy, the sales of refrigerators in A class or more (A+) accounted for 15% of all sold refrigerators, reaching almost 87% in 2008. The average energy consumption of the appliances strongly falls. Considering 100 the consumptions of 2003, we arrive at 81% in 2009 for the freezers, 86% for the refrigerators, 90 and 91% for the washing machines and dishwashers. In 2011, the European Union introduces a new energy labelling, because the old one is calibrated on obsolete energy classes thanks to the reached level of technology and energy efficiency. The new label includes three new classes (A+, A++ and A+++): the last one is the most virtuous and recently introduced.

| EFFICIENCY: THE VOICE OF PEOPLE WHO CREATE IT “I remember that, when we started talking about the energy efficiency, the products in A class did not exist. Among the technicians themselves there were those who said that the A class was impossible to achieve. This is simply because those who designed the appliances have never paid particular attention to energy efficiency”, says Marco Signa, Energy Strategy and Innovation Senior Manager at Whirlpool. Everything has changed since then, and “from that moment on all development and research programs have been focused on the efficiency improvement, in order to try to set up development programs for all categories of product, to meet the market requirements”. Is it still possible to improve the energy efficiency of the appliances? “Today - says Marco Signa - the greater potential to further optimize the consumption of electricity is in the synergies between the appliances and between the appliance and the network”. |

Integration with the renewable sources

The energy that costs less is that which doesn’t exhaust itself or which is produced at no cost: so is the energy produced by the sun. The evolution of washing machines and dishwashers goes in this direction: to develop the ability to use water heated by the sun, integrating renewable energy in daily life. The companies that are bringing these models on the market estimate savings of up to 90% in electricity consumption of dishwashers and washing machines and a reduction in consumption per every washing cycle. But the development continues and in May 2013 Miele has installed its first solar dryer: according to the German company this innovation can bring to energy savings of 60% compared to the dryers with heat pump.

| ZEOLITE: NOT PRECIOUS, BUT VIRTUOUS The zeolite is a strange stone, called “boiling stone”. The name has been given by Axel Fredrik Cronstedt, one Swedish researcher who observed that, wetting the stone, it is possible to obtain heat. The stone, cooling and drying itself, comes back to its initial state, reusable for a new cycle of heat production. A property undoubtedly interesting! Think of it in a dishwasher, where there are cycles of wet and dry. Easy to say, but it's necessary to reach this intuition. Bosch did it and for this reason has also received a recognition for the high-efficiency technologies from the federal state of Bavaria. How is this stone used in a dishwasher? In the final cycle of the program (the cycle of dishes drying), the hot and humid air is conducted to the container of the pellets of zeolite, located in the base of the appliance. The stone absorbs the humidity of the air, it emits heat, warming the air now dried that is ready to absorb new humidity. And the cycle begins again. The zeolite is able to automatically regenerate itself during each washing cycle and it should never be replaced. |

A new concept of efficiency

The integration seems to be the model of the new kitchen offered by Whirlpool: the GreenKitchenTM, where the different parts cooperate. What is waste from one part, becomes energy from the other part. Thus, the heat of the compressor of the refrigerator heats the water that goes in the dishwasher; a container under the sink allows the recovery of the clean cold water that is let to flow, waiting for it to become warm. This water can be useful for other uses, such as watering the plants, cleaning or washing the dishes. These are just two examples of what will help people to live with a sustainable lifestyle in the near future. In addition, to manage energy smartly also means to use it when it is at maximum of its availability, reaching the minimum costs. In order to do this, we have to know the trends of the energy prices and we have to start the appliance at the right time. The devices, in a close tomorrow, will be able to communicate with the network, to receive from it information about the availability of electricity and then to start at the appropriate time, by communicating with their owner, wherever he is.

The eco-friendly packaging in the household appliances

In recent years, retailers and industry talk more and more about their commitment in the development of sustainable packaging. What does this mean? Basically, it means to study solutions that can reduce waste due to packaging, realizing leaner packaging and designing completely (or almost) biodegradable or recyclable pakaging. Therefore, we present a series of proposals offered by some of the most active companies in terms of sustainability in the pack. Let’s start with Skin Pack, a package for cooker hoods by Elica Group. In the original version, it was composed of a box made in corrugated paper, a film of low density polyethylene and protections in styrofoam. In 2012 the packaging has been modified and now consists of a box made in corrugated paper (whose weight has been reduced by more than 20% without reducing the performances), a LDPE film and a tape in PP, with an increase in the value of the transportability equal to 36%. For the sustainability in the packaging of small appliances and high-tech products the proposal of Sealed Air is appealing, a company specializing in the production of packaging for food and non food. It worked to make Instapak polyurethane foam packaging greener, decreasing the weight of about 47%. At the same time, it has also reduced by 15% the carbon footprint and has limited the use of petrochemicals. Another example of eco-friendly packaging comes from Epson Italy and, in particular, from the packaging of the new range of Inkjet multifunction printers, reduced in volume by 25% compared to previous models. The new system is composed of three elements: the outer packaging in corrugated paper, reduced in weight by 16%; the container in PS (-14% compared to before); and the protective film in PP (now lighter by 45%). The limited sizes of the package allowed to load +11% of products, considering a standard pallet.

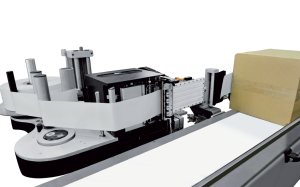

Even the most advanced brands in the world of labelling are giving their contribution in terms of sustainability. This is the case of Arca Etichette, a company that manufactures self-adhesive labels for the identification and marking of technological components and durable goods. The green novelty of Arca Etichette is the Linerless labelling. The self-adhesive labels usually are offered on a liner which then ends in the landfills, once the labels are applied on the products. In order to avoid this waste, Arca Etichette has developed the Linerless solution. Finally, a further innovation for small appliances comes from the Italian retailer Coop, which has developed an innovative model of coffee machine, designed precisely for consumers who are increasingly interested to the environmental issues. The capsules are the ecological soul of the coffee machine. They are in polypropylene with seals in aluminum and are designed in such a way that, after the consume of the coffee, all components can be easily separated from the customer, with a simple action: the emptying of the coffee grounds, after the manual removal of the cover sheet. Therefore, the innovation of the capsule lies in the easy separation of its components, allowing the recovery of the coffee grounds that can be used for the organic waste collection. And this is not a little novelty because, in general, the capsules that remain full after the use end up in the undifferentiated waste collection.