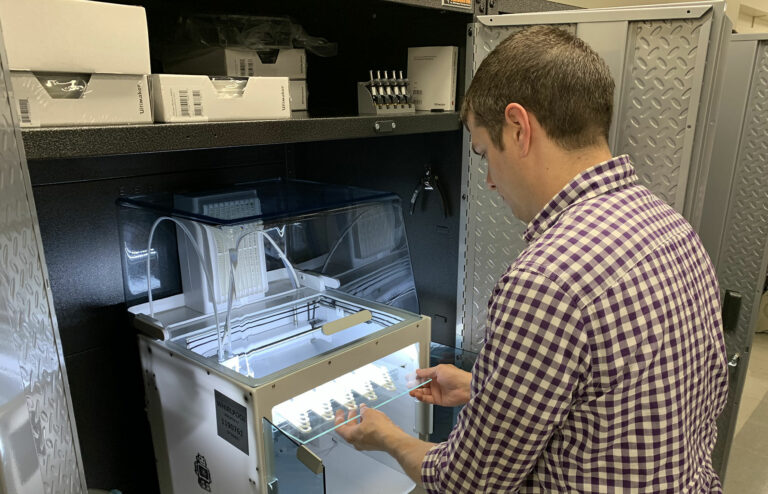

To give a concrete help to medical and healthcare workers, obliged to wear face masks during their job now focused on combatting Covid-19, one of the engineers at Whirlpool Corporation’s Ottawa, Ohio Operations, Nathan Ellerbrock, came up with the idea of creating “s-hooks” and “extenders” for medical face masks using the 3D printers at the plant. Its purpose is that of adding comfort to medical operators during the hard work they must face every day for many hours.

To give a concrete help to medical and healthcare workers, obliged to wear face masks during their job now focused on combatting Covid-19, one of the engineers at Whirlpool Corporation’s Ottawa, Ohio Operations, Nathan Ellerbrock, came up with the idea of creating “s-hooks” and “extenders” for medical face masks using the 3D printers at the plant. Its purpose is that of adding comfort to medical operators during the hard work they must face every day for many hours.

«I came across a few articles about items that are being 3D printed to support medical efforts amidst the pandemic, and I went about finding printers we had available to us that we could use to help». – Ellerbrock explained.

After conferring with other employees and doing some additional research, the team decided to print the mask extenders. Ellerbrock connected with the plant’s Environmental Health and Safety Lead, Jeff Linstedt, whose sister-in-law works in the Emergency Department at a major hospital in the area. They were given more than 200 of the extenders to trial within their organization.

«Once things were running smoothly, I kept one printer printing straps and one printing hooks nearly continuously for about a week and a half – said Ellerbrock. “I stopped counting, but I would estimate that we printed more than 300 straps and over 400 hooks for donation and internal use.»

After hearing positive reviews from that donation, the team connected with the Whirlpool Healthscope HealthCoach to reach out to other healthcare providers, including nurses, primary care offices, ambulatory care, physical therapists, and nursing homes to see if they needed the extenders as well. Those connections led to a donation of over 200 additional extenders.

«Like so many organizations and individuals in our community, Whirlpool has stepped up to support the great work of our team at St. Rita’s! – says, Beth Keehn, director of Government and Community Affairs. – Our Universal Masking policy meant that our teams were wearing masks for extended shifts and very long hours, causing headaches and ear aches. Whirlpool used their 3D printing technology to create face mask extenders, keeping our teams comfortable as they cared for our patients. We are so appreciate of Whirlpool’s generosity and commitment to the communities we serve.»