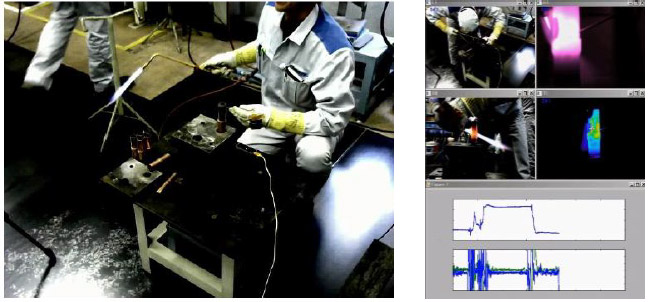

From this month, Daikin Industries and Hitachi are starting a collaborative creation aiming to establish a next-generation production model utilizing IoT in order to support skill transfer from expert workers. Daikin will introduce a system that utilizes advanced image analysis and other technologies – the solution core of Hitachi’s IoT platform “Lumada” – to enable digitalization, comparison and analysis of the skills of expert workers and trainees in the brazing process, part of the manufacturing process for air conditioners at Daikin’s Shiga Plant (Kusatsu, Shiga Prefecture); with the objective of ensuring consistent quality, improving productivity and developing human resources at production locations worldwide. Daikin and Hitachi will jointly demonstrate the viability of a production model using this system, to begin full-scale operation of the system in actual manufacturing workplaces during this fiscal year, and aim to expand applications of the system to other Daikin factories and manufacturing processes worldwide.

Starting from the joint demonstration experiment, Daikin and Hitachi plan to advance their collaborative creation towards the realization of a next-generation production model, in which global locations coordinate and share their information, skills and techniques utilizing advanced IoT.