Under the direction of the new managing director Luciano Antonini, Zepa aims to place the client more and more at the center in order to better understand his needs and to fully satisfy them

by Elena Corti

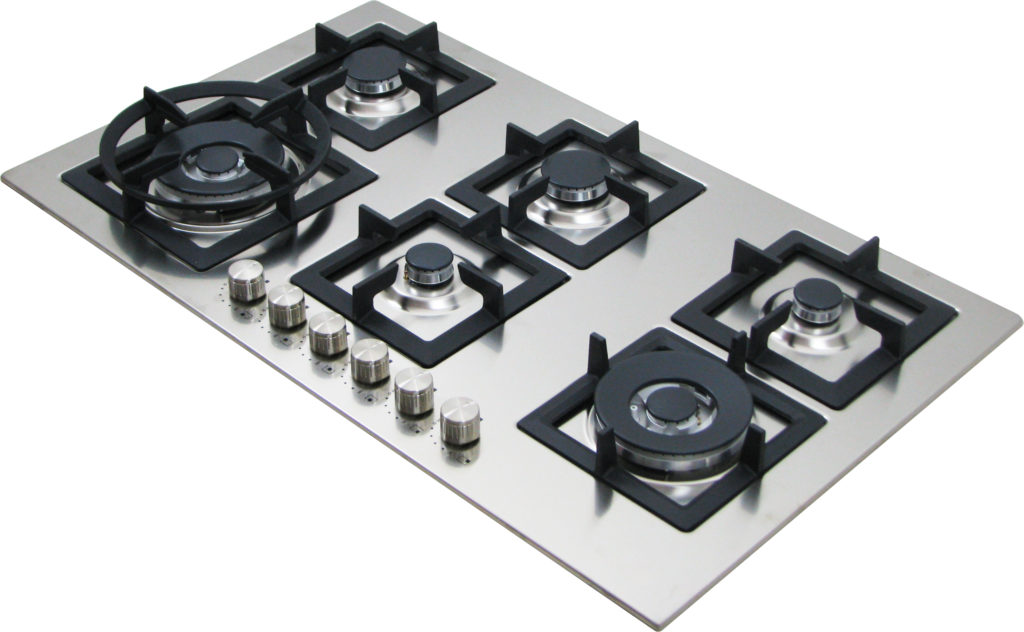

High technical expertise, care to design and innovation are the strengths of Zepa, that realizes hobs appreciated in the world as a made-in-Italy expression for the quality of their materials, the high technological level of the products and the care to details. The company exports about 90% of its hobs production, particularly in Central and South America, Middle East and Far East. Zepa was born at the end of the 1960s as a dies manufacturer and this has enabled it to develop an important know-how that is a distinctive feature of the company still today. Subsequently, it created the hobs division, producing an average of about 180,000 units per year.

Since 2007 it has joined Teka Group, a multinational company specialist in the manufacturing and sale of kitchen home appliances, bathroom products and industrial containers: the company, located in Veneto (region in the North-East of Italy) is now the expertise center for the development of the Group’s gas hobs thanks to its extensive experience in engineering. Since September of the last year, Zepa is led by Luciano Antonini, new managing director, to whom we asked to illustrate goals and planned strategies for the next future.

Eng. Antonini, what are you bringing in terms of past experience to Zepa?

I mainly bring the know-how developed in some companies of the industry, both in a large multinational corporation and in a smaller company. In particular, I introduced in Zepa new management methods to improve teamwork and follow the Lean methodologies. In addition, I also bring to the company the experience gained in the design of gas hobs, useful in stimulating innovation and development of new products.

In your opinion, what features cannot be missing in a managing director?

Certainly I would say: wish to get back in the game, enthusiasm and technical skills.

What are the goals that you want to achieve in Zepa?

The main goals are to take the company back to pre-crisis levels in the coming years, substantially increasing the revenue by 20%, and consolidating the ability to develop and innovate new products because product is on the basis of development. In fact, if a company manages to realize a good product, it sets the basis for an organic growth. Our ambition is to bring gas appliances to the market, equipped with an electronic support that allows to have better performance at reasonable prices. We want to “rejuvenate” the gas product through the use of electronics to offer more interesting performance to the market. In addition, we do research on materials, evaluating for example the use of nanotechnologies to obtain special finishes to propose to our customers. The hobs aesthetic look is important because our products must be harmonized with the kitchen furnishings.

What strategies will you undertake to achieve the set goals?Regarding products, as I said, we are doing research about materials by relying on specialists in the industry. Moreover, with regard to design, both internal designers of Teka Group and external ones are working with us. At the customer relationship level, however, we aim to be more and more proactive and market-oriented. The product-oriented company model (exclusively focused on the product) now belongs to the past: today it is extremely important to understand what the customer needs are to offer the right solutions.

Do you also offer customized solutions?

Of course. And we also try to understand – depending on the geographic areas and the type of customer we are dealing with – what are the needs of the end user, that is the customer of our customer.

Can you indicate three adjectives to define how you see Zepa under your direction?

I would say innovative in products and behaviors, ambitious and concrete. Innovative, because it is made up of people who want to do things in a differently way from how they have always done them. Ambitious, because it is made up of people who wish to reach some goals; and concrete, because if a company does not succeed in giving concreteness to its strategies, they remain only dreams.

From your answer, it is clear that human resources are very important for you.

In my experience I learned that the most significant element inside a company is just the person. Finding technology and financial resources today is, after all, easy; instead, having motivated and competent people is more difficult: I really believe in teamwork.

In your opinion, what are the main levers to encourage the motivation of the staff?

An important leverage is the economic one, for example giving the opportunity to receive prizes based on the company’s results. Another important lever is the ability to pull personal motivations out of the singular persons, channeling their ‘wish to do’ so that it is functional to the team’s goals.

Especially at this time, do you think it is important to make training to acquire new skills in the company?

Absolutely yes, we are implementing a training program at all levels: from the workers to the managers, to whom, for example, a training activity is addressed about specific but also managerial skills. In the second part of the year, half of my team will be engaged in a leadership and communication training course. In addition, we are also working to activate the school-work alternation in the company as provided by the “Good School” Italian plan to give students the opportunity to become familiar with the professional world. Training for us is crucial: we would not be coherent if we said that people are important but then we did not support them in being able to play the role they should.

Given the importance for Zepa to acquire technological expertise, do you consider the Industry 4.0 program interesting?

Yes, we are currently in the phase of gathering information to understand the steps we can actuate in the short-medium term and analyzing what will be the priorities we will have to follow first.

What are the strengths of Zepa hobs and what are their most appreciated features by the customers abroad?

Certainly, quality is appreciated, especially with regard to steel hobs because we are among the few companies able to build dies too, having an extensive expertise in this field. The variety of the range, our design and the products performance are also considered positively, in line with the market demands. In addition, our hobs are appreciated because they are considered an expression of made-in-Italy.

How made-in-Italy is concretized in Zepa products?

It is concretized in products featuring an high quality level, an accurate design and high performance. These are the three factors that distinguish the Italian product. Our customers turn to us just because they want made-in-Italy.

What are the latest products news proposed by Zepa?

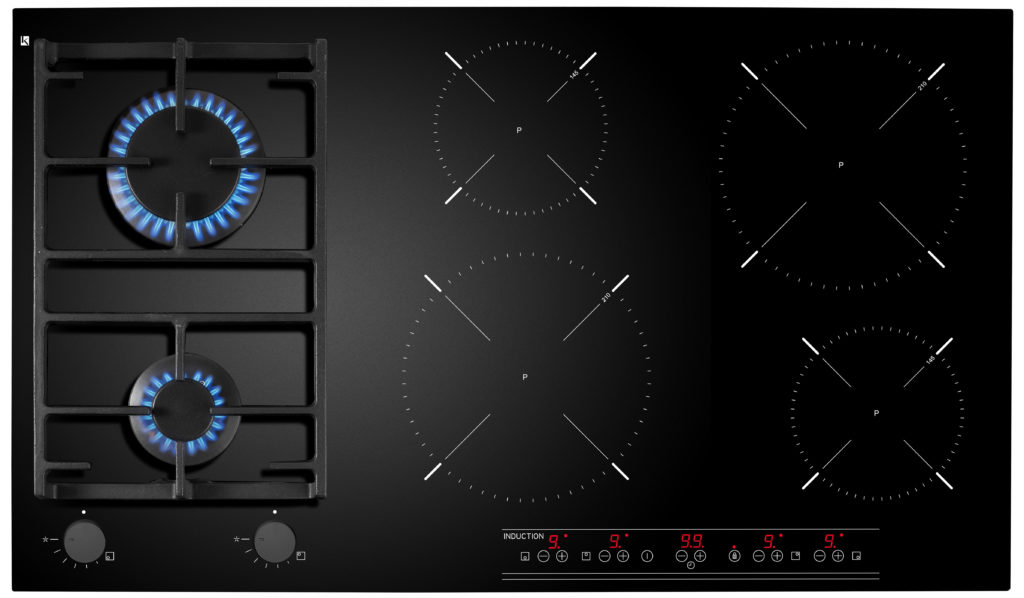

This year we have ended the renewal of the steel products range, we have completed the remake of a vitroceramic hob line and introduced a new hob line with mixed energy source, combining both induction and gas technology. We have found that in many markets there is interest in these products that synthesize the best of both types of cooking. In addition, we are already setting what will be the base of new products for 2018 and 2019: we started working on a medium-term plan with the goal of designing more and more “Lean” appliances, which are more easily producible but keeping those qualities I mentioned earlier.

To conclude, can you tell us more about the activity of dies manufacturers?

We are extremely qualified because we boast about fifty years of experience. This activity represents 15% of our business and allows us to offer customers not only finished products but also dies for their own production of gas hobs. There are few companies that offer this kind of expertise.

| Zepa in figures |

| Foundation: 1969 |

| Acquisition by Teka Group: 2007 |

| Turnover 2016: 20 million euros |

| Revenues forecast 2017: 22 million euros |

| Employees: more than 100 |

| Production site: Pianezze (Vicenza, Italy) |

| Yearly hobs production: about 180,000 |

| Exported products: about 90% |