Four models to follow and ten wastes to avoid to win the race toward new products with high added value. Here are the results of the Observatory of Collaborative Processes Management of Design of the Milan Polytechnic University

by Lara Colombi

In an economic environment characterized by an increasingly global competition in the markets, Italian manufacturing must learn to manage in a more efficient way the development and design processes. In a few words it must be able to “innovate”, always and without waste.

Also because the upset rise of firms from emerging countries, advantaged by the well-known low costs, is forcing the other companies to a revision of their competitive positioning, increasingly focused on the creation and development of products and solutions with high added value, innovative and performing, that must be available for their global customers in rapid and sure time.

In the world of home appliance as in other worlds.

But unfortunately there is not a single recipe or an always valid reference model in order to improve the effectiveness and efficiency of the phases of research, development and engineering, key for the survival and the success of businesses.

There are four. This is the main thesis of the new 2014-2015 report of the Observatory GeCo (Collaborative Process Management of Design) of the Polytechnic University in Milan, based on a series of surveys among more than 400 small, medium and large Italian manufacturing companies from four industrial macro-areas: Mechanical, Components and Plant, Electrical and Household Appliances, Electronics and Telecommunications, Other sectors such as Chemicals, Food, Textiles and Fashion.

According to the study, innovation cannot be outlined in a monolithic idea, but in a varied vision, in which each company is in the potential condition to create its own recipe, combining common ingredients in an original way, according to the rules of “just enough “(and the “common sense”).

So the researchers defined the four “archetypes of innovation” models of the manufacturing Italian world, combined to the “Fantastic 4” of the famous Marvel comic to make the concepts immediate, and then have defined the main competitive performances for each one.

The model of “customer-oriented design”, associated with Thing, allows «to be competitive in costs and times and particularly oriented to customization, with a higher level of promptness, punctuality and quality than the others competitors,” said Monica Rossi, research manager of the GeCo Observatory.

The second model, inspired by Mister Fantastic, is based on a formal approach and is planned on the design, «with performance measurements and a constant written updating of projects: it allows costs and time savings and flexibility in projects, so a competitive advantage especially in innovation.»

A third model, the Invisible Woman, is based on collaborative design, that is a simultaneous exploration in team of different alternatives, and allows to be competitive in flexibility and costs and to be better than the competitors especially in the timeliness and punctuality as well as in quality. It is the favorite model of SMEs: 33% of them use it. Finally, the fourth model is based on sustainable innovation (associated with the Human Torch), that is sustainability and innovation of products through the attention to logistics and to the second part of the product life cycle: «It allows to be competitive in products differentiation, obtaining advantages for their quality and variety.»

In practice, however, these competitive advantages are often partially foiled by inefficiency and wastes, on which the last part of the analysis of the Observatory focuses.

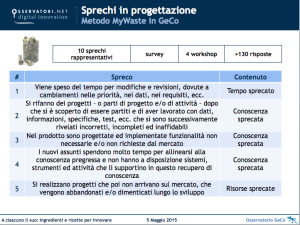

At first place in the top 10 of wastes is ranked the need to spend some time for changes and revisions, due to changes in priorities, data, requirements: 91% of companies report it often or sometimes inside their organization. For 83% wastage corresponds to the fact that the new employees spend a lot of time to align with the prior knowledge and do not have systems, tools and activities available to support them in this recovery of knowledge. For 78% of companies, however, it is necessary to make the projects again (or part of them) after discovering they have worked with data proved, later, to be incorrect or incomplete.

At the base of the podium, there is the waste of time spent for entering project information in multiple information systems, manually transcoding data and codes: it was found by 72% of companies. According to 70% of societies, what closes the top 5 is the waste of resources resulting from the over design of the product, with a consequent growth of development costs.

And while 67% of companies often, or sometimes, find to have entered the market defective products that require further repairs, 59% see two different wastes: the realization of projects that do not reach the market and the need to remake projects already developed but of which the previous knowledge has not been recovered.

Other elements close the top 10: the waste of knowledge related to having designed, in the product, features that were not required by the market (event reported by 55% of companies) and the waste of time resulting from the lack of signatures or authorization of managers who do “the stopper” (noted by 46% of the examined businesses).

So, in the Top 5 of the problems generated by these wastes we can find: for 95% of companies, too many requests for modification of the projects; for 88%, an overload of the designers; for 84%, the exceeding of the estimated costs. Passing the estimated time is instead a problem for the 73% of companies, while too much time spent on documentation of designers was found by 67% of the firms.

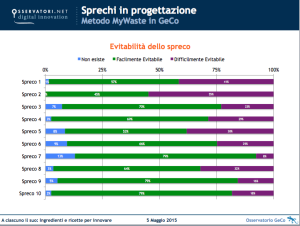

Furthermore from the survey results a certain fatalism: wastes for many would be easily avoidable. Even if they are not tangible and measurable. For this reason, with a long work, the researchers of GeCo Observatory have developed a so called MyWaste model, measuring the index of ” potential waste”, and the index of intervention priority.

Obviously, to be able to orient the design in the company towards reductions of waste and growth of competitiveness, there are the four models already undertaken by the analyzed organizations by which all companies can be inspired to create their own recipe of innovation, combining common ingredients in an original and unique way.